CONDITIONERS

The art of conditioning

At Van Aarsen, we master the art of conditioning. Our conditioners precisely balance moisture, temperature and retention time to optimize feed structure and hygiene. This enhances pellet quality and biosecurity, increases pellet mill capacity and ensures consistent, high-quality results with every batch.

At Van Aarsen, we understand that optimal conditioning means different things for different feed producers. Whether you’re producing standard compound feed or sensitive poultry diets, precise control over temperature, moisture and retention time is essential for pellet quality, process stability, and hygiene.

Our conditioners inject steam evenly, transfer heat rapidly and secure optimal moisture absorption, keeping the process under full control.

With options ranging from standard Steam mixers to a Hot Start execution and the extension with a Long Term Vessel, every producer can configure a system that meets their formulation and regulatory requirements. The result? A stable process that delivers consistent pellets, ensures feed safety and prevents waste.

Benefits of our Conditioners

- Enhanced Feed Quality: Precise control of moisture and temperature improves feed structure and hygiene, enhancing pellet quality.

- Increased Efficiency: Achieve up to 20% more pellet mill capacity with lower energy consumption, optimizing the entire feed production process.

- Improved Biosecurity: Efficient heat treatment and extended retention times eliminate harmful bacteria and pathogens, ensuring the production of safe, hygienic feed.

- Durable Design: Crafted from steam-resistant stainless steel, our conditioners are built to last, reducing maintenance costs while ensuring reliable operation.

WHY CHOOSE VAN AARSEN CONDITIONERS

EXPLORE OUR CONDITIONERS

Find answers to common questions about our co-creation process, the benefits of optimizing total cost of ownership, and how Van Aarsen’s tailored solutions help you achieve

long-term success.

Download our datasheet to see how Van Aarsen Conditioners can enhance your feed production process.

Steam mixer

The Steam Mixer is the core of our conditioning technology. By injecting steam evenly into the feed, it provides the basis for a reliable and consistent conditioning process.

The single Steam Mixer is the straightforward solution for uniform steam distribution in the feed.

The double Steam Mixer adds more retention time inside the mixer, ideal in situations where more intensive mixing with steam is required.

To ensure smooth production from the very first second, Van Aarsen offers predictive steam dosing with standard Steam Mixers. This intelligent system prevents the typical start-up issues where feed can be too dry or too wet, ensuring a fast and stable start-up, consistent product quality and reliable pellet press operation.

Hot start steam mixer

The Hot Start Mixer takes conditioning one step further. Where a standard mixer may need time to reach the right temperature, the Hot Start guarantees 100% heat treatment from the very first product.

This makes it the ideal choice for feed types where hygiene is critical, such as poultry feed. But the advantages go beyond hygiene:

No waste: With standard mixers, the first part of a batch can be too wet or too dry, leading to product loss or re-run. The Hot Start eliminates this problem completely.

Reliable pellet press start-up: Fom the very first second, the product has the right properties for pressing, avoiding start-up problems and ensuring continuous, efficient operation.

After the start-up phase, both the Hot Start and the standard Steam Mixer work in exactly the same way. The difference lies in the added efficiency and hygiene assurance at the start of every batch.

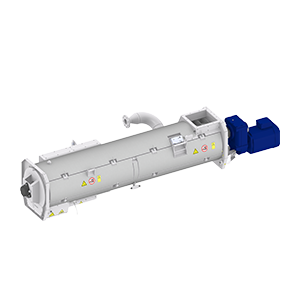

Long term Vessel (LTV)

The Long Term Vessel (LTV) is Van Aarsen’s hygienizing conditioner that extends the retention time of the feed. This ensures the product stays at the right temperature long enough for safe, high-quality conditioning.

Recently redesigned, the new LTV combines higher performance with a durable construction and easier maintenance.

Key benefits:

Consistent product flow: The redesigned screw shaft and Twin Screw Feeder provide a stable feed up to 75 t/h, boosting capacity and process stability.

Easy maintenance: Direct access to all critical components makes cleaning and inspection faster and safer.

Enhanced temperature control: Optimized tracing and smart sensors guarantee accurate monitoring and reduce contamination risk.

Flexible retention time: Adjustable from 30 seconds up to 6 minutes, ideal for starch gelatinization and hygienization of poultry feed, including sensitive types such as grandparent stock.

Steam Control Unit

Stable and precise steam flow is crucial for durable, hygienic pellets and efficient energy use. The Van Aarsen Steam Control Unit actively regulates the amount of steam entering the conditioner based on process conditions, maintaining the correct heat and moisture levels in the feed.

By continuously adjusting the steam supply, it ensures consistent starch gelatinisation, protects equipment from pressure fluctuations or condensate buildup, and supports reliable, high-quality feed production. Fully integrated with the Van Aarsen (Hot Start) Steam Mixer, the unit combines precision control with robust, long-lasting performance.

Steam Reducing Unit

Steam is essential for conditioning and achieving consistent pellet quality, but raw boiler steam often enters the process at pressures and temperatures that are too high for safe use.

The Van Aarsen Steam Reducing Unit carefully reduces and stabilises the steam to the exact pressure and temperature required for the conditioner. Excess condensate is removed, ensuring dry, saturated steam that protects equipment from water hammer and maintains consistent moisture levels inside the conditioner. Built with high-quality Spirax Sarco components, the unit delivers safe, efficient, and reliable performance in demanding feed mill environments.

Customized solutions

Van Aarsen understands that every feed mill is unique. We offer customized solutions that can be seamlessly integrated into your production line, from stand-alone conditioners to fully integrated systems designed to meet your specific needs. Whether you require adjustments to steam injection, moisture control, or pellet production, we work with you to optimize every aspect of your feed conditioning process. Contact our team today!

Related products you may be interested in

COMPLEMENTARY SOLUTIONS

Enhance your feed production with complementary solutions such as our Dosing Unit or our Pellet Mill.

Connect with our experts

YOUR PERFECT FIT BEGINS WITH A CONVERSATION

Our experts are ready to help you optimize your feed milling process and stay ahead of industry trends. At Van Aarsen, we share our knowledge and collaborate with clients to create solutions that deliver real results. Connect with us today to explore how we can support your business.

If you’re ready to enhance your feed mill operations with advanced automation solutions, contact Van Aarsen today to learn more about how we can help improve your production processes.